Clasificación del producto

Contacte con nosotros

Correo electrónico

Hm@heatmatetech.com

Línea directa de servicio:

400-812-2880

Steam Thermal Battery

Palabras clave:

Clasificación:

Detalles del producto

|

PARAMETE |

||

|

Model |

HM-150S2800 |

HM-150S8400 |

|

Working temperature (℃) |

160~400 |

160~400 |

|

Heat release power (kW) |

60~200 |

150~600 |

|

Heat storage capacity (MJ/kWh) |

2800/780 |

8400/2340 |

|

Weight of steam produced (t) |

1 |

3 |

|

Electric heater power (kW) |

120 |

360 |

|

Weight (kg) |

9000 |

30000 |

|

Dimension (mm) |

Φ2200×2350(H) |

Φ3250x4500(H) |

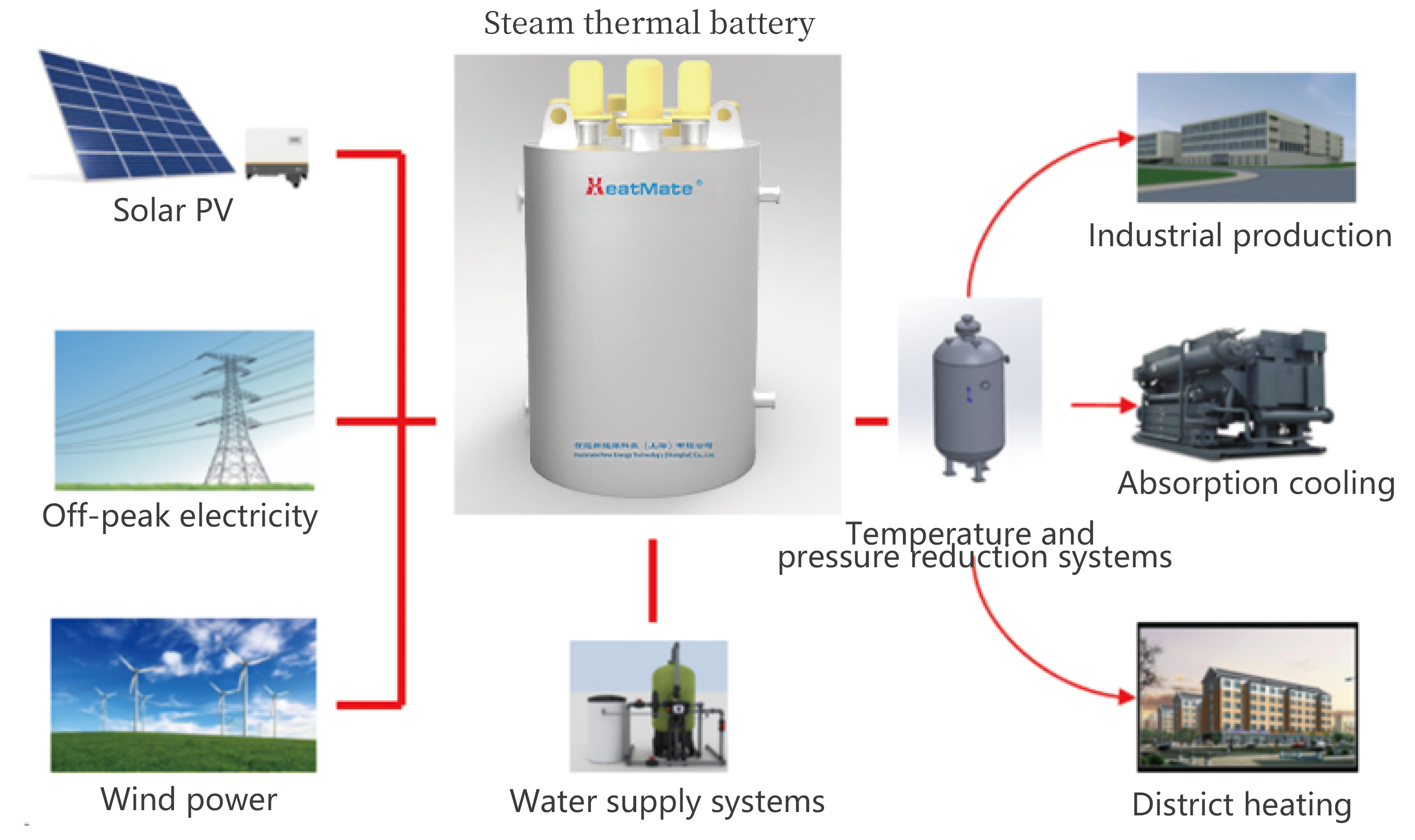

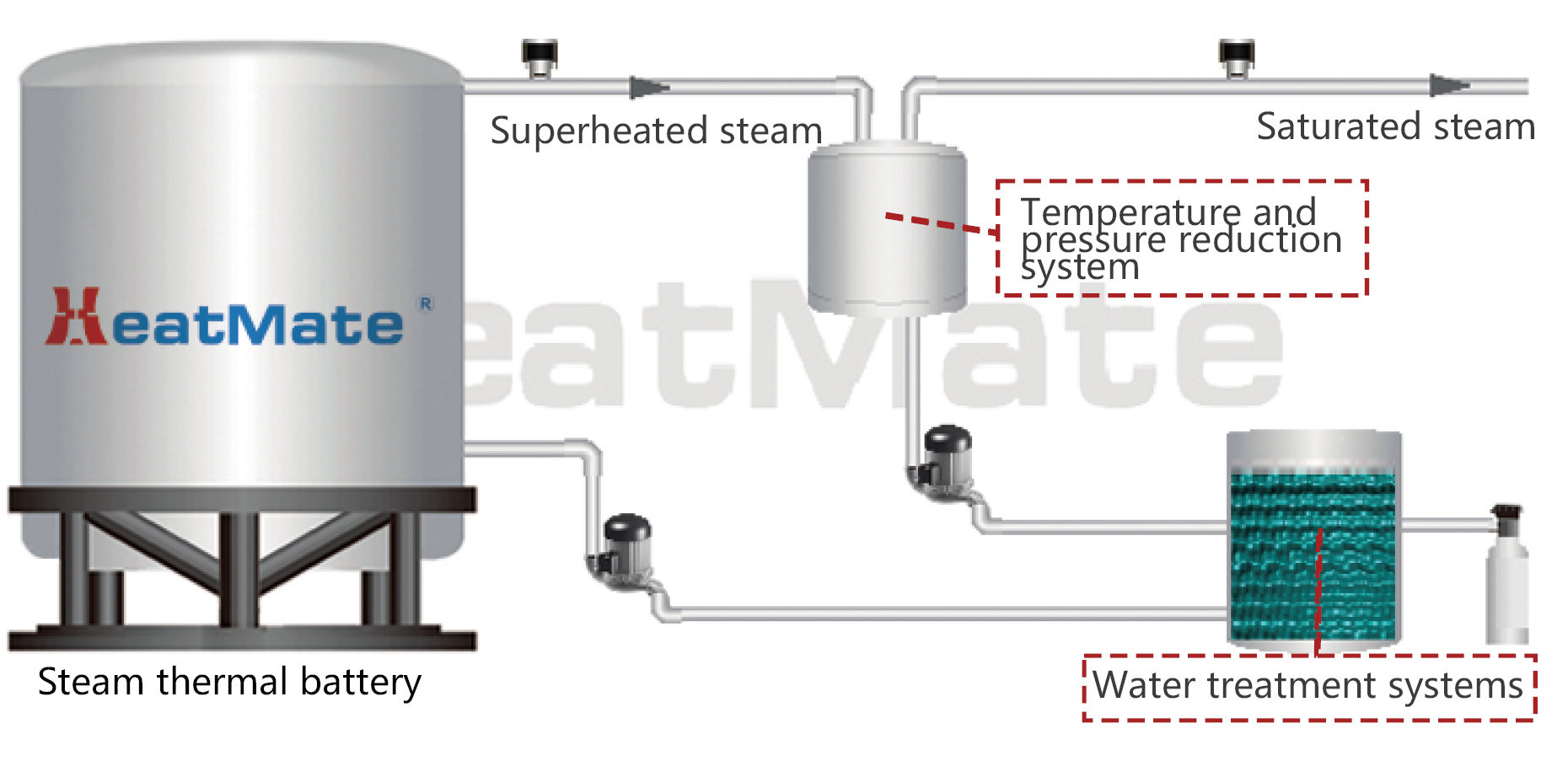

The steam thermal battery, developed by Heatmate, is an integrated high-temperature phase-change heat storage and steam production system. Using proprietary nano-eutectic phase-change material, it includes a built-in electric heater. After connecting power supply and piping, it can be used to store heat during charging periods and generate steam with the stored heat during discharge periods. Activate the electric heater, and the steam thermal battery starts to store heat. The water supply system provides water to the steam thermal battery, where it is vaporized to produce superheated steam. This superheated steam then enters the temperature and pressure reduction system, resulting in saturated steam for output.

Product Feature

- Mature technology, stable cyclic performance, safety and environmental protection, moderate cost.

2. The phase-change energy storage technology can help the peak shifting and valley filling of the power grid, greatly reducing the peak and valley difference of electricity consumption, scientifically saving fossil energy consumption in power plants, and cutting emissions off-peak.

3. The cost of phase-change materials for thermal energy storage is one-fifth of the cost of electrical energy storage.

4. Introducing other clean energy sources such as valley power, solar energy, wind power, industrial waste heat, etc., which greatly reduces the operating cost while reducing unnecessary energy loss in the production process.

System Components

01、Water Supply System

Pre-treatment of water for the system, providing the wateer source that meets the process requirements for the production process;

02、Steam Thermal Battery System

The core equipment of the system, which converts low-copst electric energy into heat energy and releases the stored heat energy in a controlled manner;

03、Temperature And Pressure Reduction System

The generated superheated steam is processed to saturatedsteam as required.

04、Pipe System

To provide water and steam at the required temperature and pressure.

05、Control System

Comprehensive monitoring of system operations, adaptive adjustment of system pressure and temperature, the remopte monitoring ensures safe and stable operation.

Operation Mode

【 Heat Charging 】

Activate the electric heater, and the steam thermal battery starts to store heat.

【 Heat Release 】

The water supply system provides water to the steam thernnal battery, where it is vaporized to produce superheated stearm.

This superheated steam then enters the temperature and pressure reduction system, resulting in saturated steam for output.

Application Scenarios

Página anterior:

Página siguiente:

Consulta del producto

¡* Por favor deje su número de teléfono y nos pondremos en contacto con usted dentro de 24 horas!